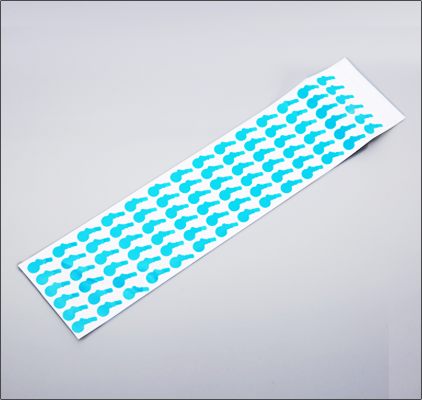

First, the tape overflow problem Because of improper storage of materials, improper handling of coils or improper operation of processing procedures, double-sided plastic die-cutting in the process of die-cutting is prone to tape overflow problems, affecting its product quality.

In order to solve the problem effectively,Attention should be paid to starting from the following aspects:

(1) Purchase suitable adhesive materials (2) when storing tape, complete seal with plastic bag to prevent moisture absorption (3) Reduce the tension of discharge while reducing the coiling tension (4) that is, remove the edge material after punching

(5) Consider the change of temperature and humidity (6) The use of dyeing printing to determine the depth of die-cutting so that in the processing process timely adjustment.

Second, indentation problem

Useful.Double-sided adhesive die-cuttingShould try to avoid the use of the process to produce indentation problems, so as to affect the smooth production;The indentation problem of double-sided adhesive die-cutting comes from a variety of possible scenarios:

1, one of the main conditions is uneven pressure, may be due to double-sided plastic die-cutting steel knife, steel line distribution is uneven, should be installed on the die-cutting plate balance knife line, so that the Platform force is uniform, if the platform before

After the more serious pressure inhomogeneity occurs at the posterior corner, the die-cutting base shield should be opened to check whether the pendulum rod is worn and whether it needs to be replaced.

2, another major situation is the explosion line, bursting color, especially such as black double-sided adhesive die-cutting process, should pay attention to prevent excessive pressure, at the same time choose the appropriate width and thickness of indentation mold.

ThreeDie-cutting processing plant

1, the above is common in the market 2 large-sided plastic die-cutting problems often occur in the use of the process, in addition to, we also need to pay attention to the purchase of environmentally friendly non-toxic double-sided adhesive materials, to prevent double-sided glue

The cutting end surface is not straight, the product sticks to each other and so on small problem.

2, the above can be seen, professional double-sided adhesive die-cutting requires producers in the use of its process, pay attention to all aspects. It is hoped that the information provided by the Bai Mei section will help you, or

Call inquiries to discuss morePrecision Die CuttingDie-cutting products.

Related News

- The usability of high viscosity protective film die-cutting

- The structure classification of common die-cutting products has these

- Protective film die-cutting process often encountered problems how to solve the problem

- Viscosity problem of heat conduction double-sided adhesive die Cutting

- Thermal material die-cutting actually has such a role

- Classification of die-cutting products in Chinamo cutting plant

- Pay attention to these contents in die-cutting machining process

- What is the "favorites required" detail about the die-cutting project workflow?

- How to calculate the cost of die-cutting processing

- Common knowledge of mesh die-cutting materials-mesh yarn materials

- Die-cutting process discussion on common problems in die-cutting industry

- How to choose the right die-cutting prototype

- Graphene Thermal conductive film leads the new direction of heat dissipation material

- How to develop the future of die-cutting processing plant