Die-cutting materials commonly used in die-cutting processing plants are: protective film / double-sided adhesive / conductive shielding composite material, die-cutting - use the mold to cut the specified material out of the desired shape to meet the customer's needs during assembly.

Adhesive—As a self-adhesive seal, it can be used to bond electronic products with lenses and liquid crystal displays, such as cell phones, PDA products, notebook computers, and the like. Not only does it provide excellent bonding, but it also provides shock absorption and aesthetics. Die-cutting - Use a mold to cut the specified material out of the desired shape to match the customer's needs during assembly.

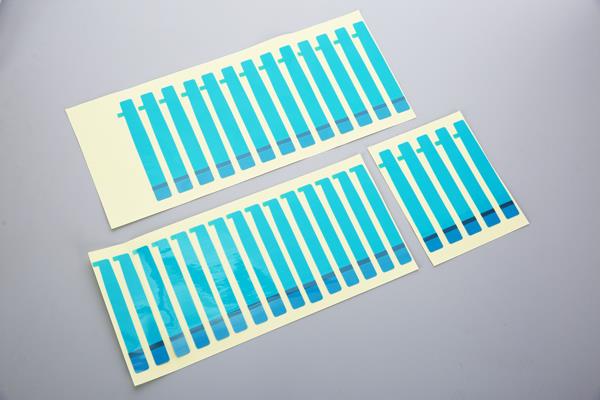

【Protective film die cutting class】

The protective film can be classified into low viscosity, medium viscosity, and high viscosity according to its adhesiveness. The viscosity can be selected according to the self-property of each industry.

In the liquid crystal display, various optical films such as a polarizing plate, a phase difference plate, and a diffusion plate are laminated.

In order to protect these optical films during the manufacture, processing, and transportation of these optical films, protective tapes are widely used. The material has a very high degree of transparency and therefore does not detract from the appearance characteristics of the product. Since it is a lightly bonded type, adhesion and peeling can be performed under low tension.

1, plasma TV screen protector

2, laptop screen protector stickers

3, LCD screen protective film protector

4, game machine LCD screen protector protector

5, electrostatic protective film, electrostatic adhesive protective film paste

6, electronic dictionary liquid crystal protective film

7, mobile phone digital camera camera screen protector

8, car DVD display GPS liquid crystal protection film

9, PET polyester film surface hardening treatment (membrane switch material)

10, liquid crystal photoelectric series; LCD liquid crystal display, backlight board, EL electroluminescent film, conductive film switch, touch screen, computer display surface protection

11. Plastic injection molding products: ABS, PP injection molding products, PVC sheet, acrylic sheet, instrument panel, plastic lens surface protection

12, brand-name printing: PVC, PC, aluminum, copper and other metal, plastic brand name surface protection

[Double-sided plastic die cutting class]

It is applied to the bonding, fixing, conducting, insulating, anti-vibration, sealing, dustproof and light-proof between various parts.

Material suppliers: 3M (USA), TESA (Texa, Germany), NITTO (Japan Nitto), SONY (Japan Sony), DIC (Greater Japan), SEKISUI (Japan Sekisui), TERAOKA (Japanese Temple), Taiwan Four-dimensional and Chinese mainland produce a variety of single and double tape. Materials suppliers: DUPON (DuPont, USA), GE (US General), TORAY (Japan Toray) MITUBISH (Mitsubishi), SKC (Korea), INOAC (Japan), RIC (Japan) and materials produced in mainland China.

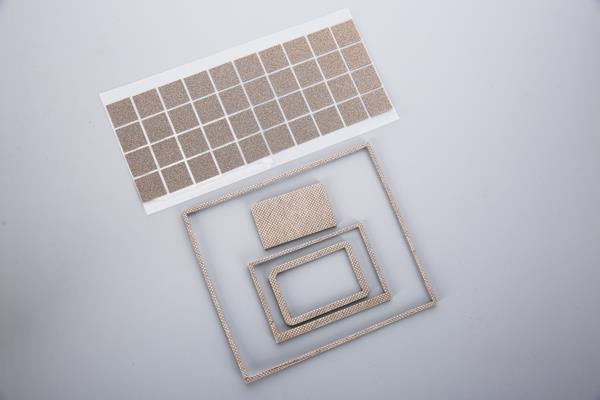

[Conductive shielding material die cutting class]

Main functions: conductive shielding, one side of conductive side insulation, double-sided insulation middle conduction to prevent looseness, prevent impact noise, prevent sticking, etc.

Main materials: imported and domestic conductive foam, conductive cloth tape, conductive copper foil tape, conductive rubber, etc.; copper foil (Cu), aluminum foil (AL), Mylar thermal conductive film; insulating sheet; barley paper; KAPTON (gold) Finger); fire fast paper: composite materials (Cu-PET, AL-PET), EMI and other composite materials.

(1) Around the LED: Prevent light leakage, absorb shock, and improve airtightness.

(2) The lower periphery of the PCB: absorb shock, absorb vibration, fill gap, and heat insulation effect.

(3) Keyboard gasket: rebound, no pollution, good dimensional stability.

(4) Around the battery: no pollution, absorb shock sound, improve air tightness.

(5) Foot pad: good friction, no pollution, good dimensional stability.

(6) Disk tail pad: absorb shock, prevent impact noise, and improve air tightness.

(7) Friction pad: good friction, no pollution, good dimensional stability.

(8) Cushion cover: absorb shock, block motor noise, shockproof, and improve air tightness.

(9) Around the horn: prevent noise and fill the gap.

(10) Around the LCD: dustproof, absorb shock, fill gaps, and improve shading.

Related News

- The usability of high viscosity protective film die-cutting

- The structure classification of common die-cutting products has these

- Protective film die-cutting process often encountered problems how to solve the problem

- Viscosity problem of heat conduction double-sided adhesive die Cutting

- Application of double-sided adhesive die-cutting in die-cutting

- Thermal material die-cutting actually has such a role

- Classification of die-cutting products in Chinamo cutting plant

- Pay attention to these contents in die-cutting machining process

- What is the "favorites required" detail about the die-cutting project workflow?

- How to calculate the cost of die-cutting processing

- Promote the rapid improvement of die-cut products of conductive shielding materials in the 5G era

- Mobile phone protective film die cutting process control

- Mobile phone protective film die-cutting process