Guide: With the rapid development of digital products, the application of mesh die cutting is also increasing. Today, everyone will enter the mesh.

Basic elements of mesh

1 mesh

The mesh number is a unit indicating the density of the mesh weaving (the amount of mesh contained between the meshes having a length of 1 inch)

2 wire diameter

The diameter of the wire is the thickness of the wire. As shown in the figure as TD

3 thickness

The thickness is the thickness value (measured value) when the mesh is in tension and is in a static state, and is shown as MT in the figure.

4 opening

Opening is a method used to indicate the size of the holes between the meshes. The opening is determined by the thickness of the wire and the mesh.

5 opening ratio

The open area ratio refers to the area occupied by the gap in the unit area expressed by the percentage of the mesh. The larger the percentage, the larger the opening ratio of the mesh.

6 acoustic resistance rate

Sound resistance rate = sound pressure / particle speed. It is the most important parameter related to sound. The smaller the value, the smaller the barrier to sound.

Product material classification

Polyester PET

Features: low shrinkage, high strength, acid aging and environmental protection

Self-absorbent

The aperture does not change after encountering water

Acoustic performance and stability

Nylon PA

Features: high elongation

Water absorption

The hole diameter changes after water contact, resulting in a change in the acoustic resistance rate.

Unstable acoustic performance

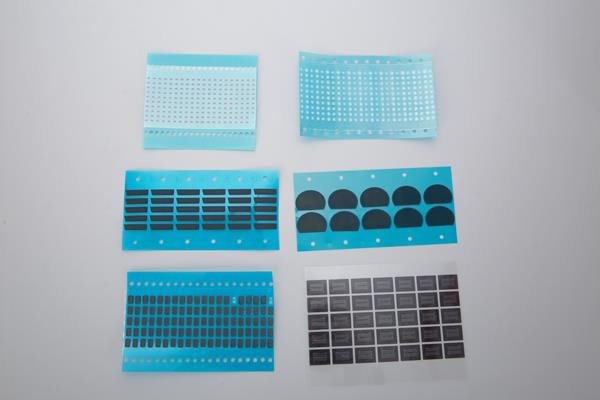

Product use classification

Air filter features:

Precise and consistent mesh size

Smooth surface

Precise filtration performance

Dust rating: IP5X

Lighter and thinner

use:

Mainly used in computer, audio, mobile phones and various speakers to protect against dust.

Excellent dust resistance, good ventilation, minimal transmission loss, stable product performance, and maximum customer satisfaction

Acoustic Mesh Acoustic Network Features:

Stable sound output

Meet all kinds of sound effects

Has been applied to mature products of various brands of mobile phones and headphones

use:

Mainly used in the speakers of mobile phones, headphones, audio and other electronic products.

The stable acoustic resistance value guarantees the sound quality of the product and optimizes the sound quality.

Waterproof Mesh Waterproof Net Features:

Waterproof treatment

Waterproof rating: IPX4

Environmentally friendly dyes and waterproof treatment

Third-party environmental test report for all products

use:

Mainly used in outdoor small speakers, microphones, computers and mobile phones and other electronic products.

Aluminium Mesh Silver Network

Light and flexible

anti-static

Anti-electromagnetic or radio frequency interference

Meet metal appearance needs

Production Process

Warping

The raw materials are finished by a warping machine onto a shaft.

2. Wear a comprehensive wear

Pass each wire through the heald and steel heel.

3. Weaving

Start the textile process → mesh forming

4. Inspection

Dimensions, density, appearance, and weaving of the woven mesh

Physical inspection.

5. Cleaning

For the thread and the oil on the mesh belt during the manufacturing process,

Dirty washing process.

6. Dyeing

The mesh color processing process is carried out according to the customer's needs.

7. Heat setting

Use a heat setting machine to stabilize the physical properties of the mesh.

8. Inspection

Detect mesh number, wire diameter, mesh size, thickness, and so on.

9. Packaging

Uniform use of paper tubes with a diameter of 7.5 cm rolled up, and then plastic

Bag packaging.

test

Mesh mesh

Thread Diameter wire diameter

Opening

Air Permitability

Mesh count

The introduction of this year's mesh die cutting is here, I want to know more, you can call us!

Related News

- The usability of high viscosity protective film die-cutting

- The structure classification of common die-cutting products has these

- Protective film die-cutting process often encountered problems how to solve the problem

- Viscosity problem of heat conduction double-sided adhesive die Cutting

- Application of double-sided adhesive die-cutting in die-cutting

- Thermal material die-cutting actually has such a role

- Classification of die-cutting products in Chinamo cutting plant

- Pay attention to these contents in die-cutting machining process

- What is the "favorites required" detail about the die-cutting project workflow?

- How to calculate the cost of die-cutting processing

- Introduction of three types of die-cut materials commonly used in die-cutting processing plants

- Promote the rapid improvement of die-cut products of conductive shielding materials in the 5G era

- Mobile phone protective film die cutting process control

- Mobile phone protective film die-cutting process