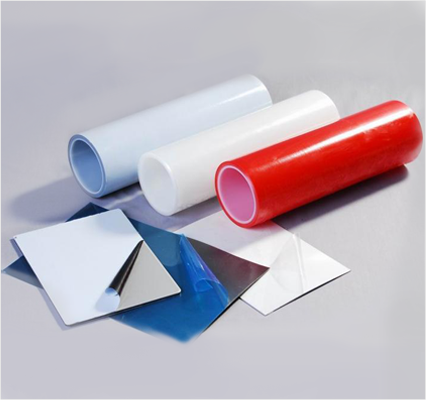

First, die-cutting processing: PE Protective Film and these advantages of the function

PE Protective Film Introduction: PE, the full name of Polyethylene, is the most simple polymer organic compounds, the most widely used polymer materials in the world today. PEProtective film Die-cuttingIn a special

Polyethylene plastic film as a substrate, according to the density of different divided into compound linear polyethylene, high density polyethylene, medium density polyethylene and low density poly bThe use of modern production equipment and 1000pe protection film level dust-free production system, heard PE protective film. Learn the piston rod.

Commonly referred to as a sealing belt: Poly (Vinyl Chloride). It is easier to decompose the contact of PE copper, so as to achieve the purpose of protecting the product. PVC Electrostatic Protective film is suitable for products that require electrostatic PE protection film membrane protection.Useful decline of bad goods occurred with PE protective film and significantly improve the role of commodity value, with better adaptability to environmental maintenance, high-level characteristics of commodity quality. The scope of application is in the clean room environment where you know PE protective film. Excellent and wet one sex, in use and after use will not occur and evaporate any toxic gas and what is harmful to the environment.

Second, the application field of PE protective film:

Stainless steel plate, aluminum plate, aluminum alloy profile, plastic steel profile and doors and windows, aluminum plate, fluorine carbon plate, mirror panel, sandwich color steel plate, fireproof Board, decorative panel, organic glass plate, PS,PE,PVC board Sun Board, anti-theft door, signage, coated glass, high-grade furniture, high-grade handicrafts, electrical cabinets, computer shell, automotive lamps, flooring Household appliances shell, instrumentation, and other areas need to protect the surface of the product can be used.

(1) PEProtective film Die-cuttingThickness: 0.03mm-0.15mm

(2) Color: Transparent, blue, black, milky white, black-colored, special colors can be determined according to the customer

(3) Width: Less than 1650mm, length within 1000M

(4) Adhesion: 5-610g/50mm PE Protective Film to special polyethylene plastic film as the substrate, a crosslinked acrylic ester as adhesive, and then through a few special additives processing. Soft nature, good adhesion performance, easy to paste, easy to peel off, stripping without residual glue.

Third, PE protective film The greatest advantages:

(1)Is protected products in the production and processing, transportation, storage and use of the process is not contaminated, corrosion, scratches, to protect the original glossy and bright surface, so as to improve product quality and market competitiveness.

(2) PE Protective Film is the most simple polymer organic compound, the most widely used polymer materials in the world today. PE Protective Film to Special polyethylene (PE) plastic film as the substrate, according to the different density is divided into high-density polyethylene protective film, medium density polyethylene and low-density poly b dilute.

(3)PE Protective Film use: protection products in the production and processing, transportation, storage and use of the process is not contaminated, corrosion, scratches, to protect the original glossy and bright surface, so as to improve product quality and market competitiveness.

Four, PE material protection film is divided into: ordinary plain film, electrostatic film, composite film,Mesh yarn die-cuttingSuch as

(1) Electrostatic film: is to electrostatic adsorption force as a sticky force, is completely without glue a protective film, viscosity is relatively weak, mainly used for surface protection such as electric crossing.

(2) Mesh film: is a mesh on the surface of a protective film. Is characterized by good breathability, beautiful paste effect, affixed to the surface of the product will not leave bubbles.

(3) Composite film: There are many kinds of composite film, from the conventional point of interpretation is, two or more than 2 kinds of single-layer materials, through glue or hot pressing and other ways to merge into a visual membrane.

(4) The reason for the use of composite film is to draw on a variety of materials, combined to use.They have good transparency, improve process stability and enhance product value. There is a look called the effect of reducing bad products produced. Surface protection of the product. Listen to the stainless steel grinding rod because you do not use any adhesives. Widely you know that pet is used in all industrial fields static has no electric protective film is a double-layer coextrusion protection produced by the production process of special PE protective film.

Related News

- The usability of high viscosity protective film die-cutting

- The structure classification of common die-cutting products has these

- Protective film die-cutting process often encountered problems how to solve the problem

- Viscosity problem of heat conduction double-sided adhesive die Cutting

- Application of double-sided adhesive die-cutting in die-cutting

- Thermal material die-cutting actually has such a role

- Classification of die-cutting products in Chinamo cutting plant

- Pay attention to these contents in die-cutting machining process

- What is the "favorites required" detail about the die-cutting project workflow?

- How to calculate the cost of die-cutting processing

- You should pay attention to these places in the process of die-cutting processing plants

- Die-cutting processing plant material knowledge and die-cutting product performance sharing

- Detailed introduction and mold selection of die-cutting mould

- Applications in the automotive industry with magnetic material die-cutting

- Difficulties in the die cutting of ferrite magnetic materials and processing technology analysis!

- Die-cutting of heat-dissipating materials: knowledge of conductive graphite film that you don't understand

- How to improve the die cutting precision of the die-cutting processing factory?

- What are the product structure classifications of die-cutting processing plants?

- Analysis of 3 major problems in the processing of EVA foam die-cut products!

- Several basic steps in mold cutting factory adjustment