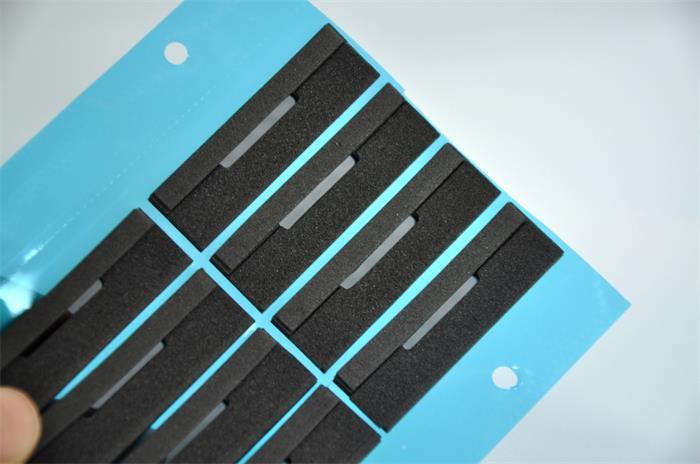

EVA foam die cutting

EVA foam is made of EVA foamed composite double-sided tape, which is processed and stamped and formed into electrical, machine, digital and other industries to play the role of anti-slip, anti-slip and cushion. Also known in the industry as EVA pads, EVA foam pads.

EVA foam die cutting:

The color is white, black, color, and white and black are often used in industry, and the color is small.

EVA hardness: 25 degrees, 38 degrees, 45 degrees, 50 degrees, 60 degrees, 70 degrees, 80 degrees, commonly used in the industry is 38 degrees, 45 degrees. Electronic internal accessories are generally 25-38 degrees.

Foam die-cut product characteristics

EVA foam has good elasticity and wear resistance, air tightness,

Water resistance: closed cell structure, no water absorption, moisture resistance, and good water resistance.

Corrosion resistance: resistant to corrosion by seawater, oil, acid, alkali and other chemicals, antibacterial, non-toxic, odorless, non-polluting.

Processability: It is easy to process by hot pressing, cutting, gluing and laminating.

Anti-vibration: high resilience and high tensile strength, high toughness, good shock resistance, anti-skid and cushioning properties.

Insulation: heat insulation, heat preservation and low temperature performance, can withstand severe cold and exposure.

Sound insulation: closed-cell foaming, good sound insulation.

Application range

EVA foam is mainly used for shock, cushioning and anti-skid selection of electronics, electrical appliances, machinery, digital, high-tech products, furniture, toys, metal plastics, printing panels and other industries.

Widely used in the prevention of electronic and electrical furniture, ceramic glass wood and other products are scratched and scratched at the bottom, can also reduce the noise generated by the movement of objects, make up for the unevenness of electrical and furniture feet, and can play anti-skid, shockproof, buffer, etc. Many functions.

Related News

- The usability of high viscosity protective film die-cutting

- The structure classification of common die-cutting products has these

- Protective film die-cutting process often encountered problems how to solve the problem

- Viscosity problem of heat conduction double-sided adhesive die Cutting

- Application of double-sided adhesive die-cutting in die-cutting

- Thermal material die-cutting actually has such a role

- Classification of die-cutting products in Chinamo cutting plant

- Pay attention to these contents in die-cutting machining process

- What is the "favorites required" detail about the die-cutting project workflow?

- How to calculate the cost of die-cutting processing

- What are the structural classifications of common die-cutting processing products?

- What are the main die-cut materials for die-cutting processing plants?

- What problems should be paid attention to during the processing of the protective film of the die-cutting processing factory?

- Introduction to materials that must be recognized by the mesh die cutting industry

- Introduction of three types of die-cut materials commonly used in die-cutting processing plants

- Promote the rapid improvement of die-cut products of conductive shielding materials in the 5G era

- Mobile phone protective film die cutting process control

- Mobile phone protective film die-cutting process